DOMOTEX asia/CHINAFLOOR: The Core Platform for the Resilient Flooring Industry

As a leading B2B exhibition for flooring materials in the Asia-Pacific region, DOMOTEX asia/CHINAFLOOR serves as a pivotal platform for the display, exchange, and business matching of the resilient flooring industry.

The exhibition features an exclusive zone for resilient flooring (covering 50,000 square meters in Halls 7.1 and 7.2 in 2025), gathering over 400 resilient flooring brands among more than 1,500 exhibitors—including Gerflor, LX Hausys, and Shengxiang. It showcases a full range of resilient flooring products and innovative technologies, such as PVC, rubber, linoleum, cork, and Non-PVC (PET/PP-based) materials.

Additionally, concurrent events like the Flooring Innovation Summit focus on material upgrades, while the Buyer Club enables precise global procurement matching, connecting exhibitors with 83,850 professional visitors (including 17,923 international buyers). Aligning with environmental trends, the exhibition highlights green resilient flooring such as carbon-negative rubber and recycled PVC, reinforcing Asia-Pacific’s position as a global hub for resilient flooring innovation, manufacturing, and trade. It has become an annual must-attend event for enterprises to expand markets and grasp industry trends.

Gerflor: 跳转到《018-Domotex Asia Exhibitor- Gerflor DLW Linoleum Flooring》

https://www.lxhausys.com/us/index

What is Resilient Flooring?

Resilient flooring refers to a category of flooring that undergoes slight deformation under external force and quickly reverts to its original shape when the force is removed. Positioned between soft flooring (e.g., carpet) and hard flooring (e.g., solid wood, ceramic tiles), its core characteristics are "recoverability" and "flexibility," balancing support and comfortable foot feel.

Core Definition and Essence

· Essence: Made from core raw materials such as PVC, rubber, linoleum, and cork through processes like calendering, vulcanization, and lamination, it possesses the physical property of "deformation and rebound," distinguishing it from inelastic, damage-prone hard flooring.

· Core Attributes: Balances "wear-resistant practicality" and "comfortable experience." It resists daily wear, cushions impacts, and reduces foot fatigue, adapting to diverse needs in residential, commercial, and professional scenarios.

Key Features

Impact Absorption & Rebound: Absorbs impact (e.g., children falling, items dropping), minimizing floor damage and injury risks—ideal for spaces with elderly or children.

2. Comfortable Foot Feel: Neither as cold as ceramic tiles nor as soft as carpets, it distributes pressure evenly during standing or walking, reducing foot fatigue even with prolonged use.

3. Versatile Performance: Mainstream products offer water and moisture resistance, wear resistance (some reaching AC5+ grade), sound absorption, and noise reduction. Materials like rubber and linoleum have natural antibacterial properties, enabling easy cleaning and maintenance.

4. Diverse Forms: Includes rolls (continuous sheets for seamless installation) and tiles (click-lock or adhesive-based with various sizes). Digital printing replicates wood, stone, and other textures, combining aesthetics and functionality.

Main Materials and Categories

· PVC-based (over 70% market share): Includes LVT (Luxury Vinyl Tile), VCT (Vinyl Composition Tile), and PVC rolls. Cost-effective and versatile, it dominates the mainstream market.

· Natural Materials: Linoleum flooring (100% natural, biodegradable) and cork flooring (renewable bark raw material, sound and thermal insulation), targeting the high-end eco-friendly market.

· Professional Materials: Rubber flooring (super wear-resistant, impact-resistant), suitable for high-end commercial scenarios like healthcare, sports venues, and airports.

What Are the Application Scenarios of Resilient Flooring?

Resilient flooring covers three core areas: residential spaces, commercial spaces, and professional venues. Its core adaptation logic is "matching material characteristics to scenario needs"—relying on advantages like impact absorption, water resistance, wear resistance, sound insulation, antibacterial properties, and easy maintenance to serve as an "all-round flooring" balancing practicality and experience.

1. Residential Spaces: Focus on Comfort, Safety, and Convenience

Core Needs: Comfortable foot feel, slip resistance, easy cleaning, suitability for the elderly/children, and balance of aesthetics and cost-effectiveness.

· Key Adaptable Spaces:

Living Rooms/Bedrooms: Prioritize click-lock LVT or cork flooring. Warm foot feel, sound absorption (reducing family activity noise), and 3D digital printing replicate wood/stone textures, adapting to modern, minimalist, and other home styles.

Children’s Rooms: Prefer antibacterial PVC or linoleum flooring. Natural antibacterial properties, slip resistance (friction coefficient ≥0.6), impact absorption (reducing fall injuries), formaldehyde-free and low-VOC, ensuring indoor air quality.

Kitchens/Bathrooms/Balconies: Choose waterproof PVC rolls or click-lock SPC flooring. Fully water and moisture resistant, oil-stain resistant, easy to wipe, avoiding mold and deformation—suitable for damp substrates.

Basements: Opt for moisture-proof PVC rolls or rubber flooring. Strong moisture resistance prevents bulging and mold, while sound absorption improves the stuffy atmosphere.

· Recommended Materials: PVC (LVT/SPC/VCT), cork flooring, linoleum flooring (for children’s rooms/bedrooms).

2. Commercial Spaces: Focus on Wear Resistance, Stability, and Efficient Maintenance

Core Needs: Withstanding high foot traffic, easy cleaning and disinfection, long service life (10-20 years), and suitability for large-scale installation and unified styles.

· Key Adaptable Spaces:

Office Buildings/Corporate Offices (Lobbies, Corridors, Offices): Select LVT tiles or PVC rolls. Wear resistance (AC5+ grade), scratch resistance (adapting to office furniture movement), sound insulation, and uniform colors for large-scale installation.

Hotels/Homestays (Guest Rooms, Corridors, Lobbies): Choose LVT or cork flooring. Wood/stone-like appearance enhances guest experience, water and dirt resistant, easy to clean with a damp cloth, reducing operational costs.

Malls/Retail Stores (Public Areas, In-store Spaces): Opt for high-wear PVC rolls or rubber flooring. Withstands over 10,000 daily footsteps, stain resistant (easy to clean coffee/beverage spills), and customizable brand-specific colors.

Schools/Kindergartens (Classrooms, Corridors, Activity Rooms): Prefer slip-resistant PVC or linoleum flooring. Slip resistance (adapting to children’s running), antibacterial and easy to disinfect (withstanding 84 disinfectant), sound absorption, and wear resistance (adapting to desk/chair movement).

Catering Venues (Dining Halls, Kitchens): Select high-slip-resistant PVC or rubber flooring. Friction coefficient ≥0.7 in wet environments, oil and acid/alkali resistant (withstanding cleaning agents), and seamless splicing (PVC roll welding for kitchens) to avoid dirt accumulation.

Nursing Homes/Wellness Centers: Choose linoleum or rubber flooring. Natural antibacterial properties, gentle foot feel (adapting to the elderly’s walking), impact absorption (reducing fall injuries), easy to clean and disinfect, and low odor.

· Recommended Materials: PVC (rolls/tiles), rubber flooring, linoleum flooring (for nursing homes/schools).

3. Professional Venues: Focus on Functional Customization and Scenario Adaptability

Core Needs: Meeting special functions (e.g., antibacterial, impact-resistant, antistatic) and adapting to the rigorous requirements of professional scenarios.

· Key Adaptable Spaces:

Healthcare Facilities (Wards, ICUs, Operating Rooms, Corridors): Select rubber flooring or PVC homogeneous rolls. ISO 10993 biocompatibility certified, resistant to povidone-iodine/alcohol disinfection, non-porous surface (preventing bacterial growth), and impact resistant (adapting to medical cart rolling).

Sports Venues (Basketball Courts, Badminton Courts, Gyms): Choose rubber sports flooring or PVC sports flooring (e.g., Gerflor Taraflex series). Rebound rate ≥90%, shock absorption (reducing athlete joint injuries), slip and wear resistant (adapting t sports shoe friction), and certified by FIBA/BWF.

Transportation Hubs (Airport Terminals, High-speed Rail Waiting Halls, Subway Stations): Opt for super-wear-resistant rubber flooring or PVC rolls. Withstands high foot traffic and luggage dragging, easy to clean (adapting to rapid cleaning), fire-retardant (grade B1), and sound absorption (reducing noise).

Data Centers/Laboratories: Select antistatic PVC flooring or conductive rubber flooring. Surface resistance 10^6-10^9Ω, adapting to electronic equipment antistatic needs, and wear resistant/stable (adapting to server cabinet loads).

Exhibition/Temporary Spaces (Exhibition Halls, Rental Offices): Choose loose-lay PVC rolls or click-lock LVT flooring. Easy installation/dismantling (completing 1,000㎡ installation in one day), reusable, and adhesive-free.

· Recommended Materials: Rubber flooring (healthcare/sports/transportation), PVC homogeneous rolls (healthcare), antistatic PVC/rubber flooring (data centers), loose-lay PVC rolls (temporary spaces).

Quick Reference: Scenario-Material Matching

· Residential Children’s Rooms/Nursing Homes: Core needs—antibacterial, slip-resistant, impact-absorbing; Recommended—linoleum flooring, rubber flooring, antibacterial PVC flooring.

· Hospital Operating Rooms/ICUs: Core needs—disinfection-resistant, antibacterial, seamless; Recommended—PVC homogeneous rolls, rubber flooring.

· Sports Venues/Gyms: Core needs—high rebound, wear-resistant, slip-resistant; Recommended—rubber sports flooring, PVC sports flooring.

· Kitchens/Bathrooms: Core needs—waterproof, oil-stain resistant, easy to clean; Recommended—PVC rolls, SPC flooring.

· Malls/Transportation Hubs: Core needs—super wear-resistant, high foot traffic tolerance; Recommended—rubber flooring, high-wear PVC rolls.

· Temporary Exhibition/Rental Spaces: Core needs—easy installation, reusable; Recommended—loose-lay PVC rolls, click-lock LVT.

Tips: Core Logic for Scenario Selection

1. Prioritize Core Needs: Safety-oriented (elderly/children) → slip-resistant and impact-absorbing materials (rubber, linoleum); Function-oriented (healthcare/sports) → professional customized materials; Cost-oriented (large-scale commercial) → PVC-based; Eco-oriented (green buildings) → natural materials (linoleum, cork).

2. Consider Usage Intensity: High foot traffic (malls/transportation) → wear-resistant grade ≥T rubber/PVC rolls; Low usage (residential bedrooms) → cork/linoleum.

3. Account for Environmental Conditions: Damp environments (kitchens/basements) → waterproof PVC/SPC; Dry high-end scenarios (villa bedrooms) → cork/linoleum.

The strong adaptability of resilient flooring stems from its "diverse materials + balanced performance." From daily residential use to rigorous professional scenarios, it meets core needs through material-process combinations, making it the fastest-growing flooring category globally.

Why is Resilient Flooring Ideal for Families?

Resilient flooring’s popularity continues to rise in the flooring industry. However, the term "resilient flooring" is broad and lacks clear defining features as it covers a wide range of products. So, what exactly is resilient flooring, and why is it perfect for families—especially those with active children?

Understanding Resilient Flooring

What comes to mind when you hear "resilient"? Ideally, a material with slight flexibility while maintaining adequate support—comforting to the feet with good bounce-back. Resilient flooring falls between soft flooring (e.g., carpet) and hard flooring (e.g., solid wood), including linoleum flooring and vinyl plank flooring.

Resilient flooring offers numerous benefits for families. Unlike stain-prone, hard-to-clean carpets or high-maintenance solid wood flooring that requires careful upkeep to prevent wear, resilient flooring is durable and easy to maintain.

Most resilient flooring is water-resistant—some flooring experts even classify it as fully waterproof. Best of all, many options are budget-friendly, allowing families to enjoy high-quality flooring at an affordable cost.

Why Families Love Resilient Flooring

Resilient flooring is a cornerstone of ideal family homes. Children love to play—whether running around the house or tracking in dirty footprints. Resilient flooring simplifies parents’ lives, letting them focus on quality time with their kids. Options like vinyl tile flooring absorb sound, preventing running footsteps from echoing throughout the house—perfect for high-traffic areas! Additionally, vinyl planks are warmer and more comfortable than traditional solid wood, keeping everyone’s feet cozy, especially in winter.

Resilient flooring boasts an attractive appearance and easy maintenance. There’s no need to worry about accidents ruining the flooring or requiring full overhauls. Even if vinyl tiles need replacement, flooring companies can complete the job quickly. Versatile enough for every room in the house, it can be installed in areas where carpet can’t (e.g., bathrooms), further preventing mishaps.

Is Resilient Flooring Right for You?

Does this describe your needs? If so, you’re on the right track to finding the perfect flooring for your family. Flooring companies rave about resilient flooring for a reason—at an affordable price, families can enjoy luxurious-looking, low-maintenance flooring without stress. What more could you ask for?

The experts at Ozburn-Hessey Company have generations of experience helping families find their ideal flooring. Don’t hesitate to contact the professionals—they have everything you need and can tailor solutions to your specific needs, ensuring satisfaction even if you’re not entirely sure what you’re looking for yet!

What Are the Advantages and Disadvantages of Resilient Flooring?

Combining product characteristics, practical applications, and industry data, the core advantages and disadvantages of resilient flooring are summarized below, covering material performance and needs in residential, commercial, and other scenarios:

I. Core Advantages

1. Balanced Performance: Flexibility + Practicality

· Impact Absorption & Rebound: Slight deformation under external force and quick recovery, cushioning impacts (e.g., children falling, items dropping) to reduce floor damage and injury risks—ideal for families with elderly or children.

· Comfortable Foot Feel: Between soft and hard flooring, warm and not cold, reducing foot fatigue during prolonged standing or walking—superior to ceramic tiles and stone in winter.

· Wear Resistance: Wear layers on mainstream materials (e.g., PVC, rubber) resist daily wear; some products reach AC5+ grade, adapting to high-frequency residential use and high-foot-traffic commercial spaces with a service life of 10-20 years.

2. Easy Maintenance + Wide Adaptability

· Water & Moisture Resistance: Most resilient flooring (e.g., LVT, vinyl) is water-impermeable and moisture-proof, suitable for damp areas like bathrooms, kitchens, and basements. It avoids mold and deformation, requiring only a damp cloth for cleaning—no special maintenance.

· Easy Installation: Click-lock or roll installation processes eliminate complex substrate preparation, shortening construction cycles. Some products can be laid directly over existing flooring, reducing renovation costs; they are detachable and reusable for flexible later maintenance.

· Strong Scenario Adaptability: Suitable for residential spaces (living rooms, bedrooms, children’s rooms), commercial spaces (hospitals, schools, offices, hotels), and dry/damp environments. Particularly ideal for scenarios requiring sound insulation, slip resistance, and antibacterial properties (e.g., easy-to-disinfect hospitals, slip-resistant schools).

3. Eco-friendliness + Cost-Effectiveness

· Outstanding Eco-friendliness: Natural materials (linoleum, cork) are 100% formaldehyde-free and biodegradable; PVC-based resilient flooring mostly uses formaldehyde-free formulas, with some products certified by FloorScore® and LEED. Recycled PVC further reduces carbon footprint.

· Aesthetics + Cost-Effectiveness: 3D digital printing replicates realistic wood and stone textures, rivaling solid wood and natural stone in appearance. Price ranges from 100-1000 RMB/㎡—mid-to-low-end PVC offers higher cost-effectiveness than solid wood, while high-end linoleum and cork meet luxury needs.

4. Rich Additional Functions

· Sound Absorption & Noise Reduction: The material itself absorbs sound, reducing noise from footsteps and furniture movement—ideal for multi-story residences, apartments, or commercial offices to enhance tranquility.

· Antibacterial & Slip Resistance: Some materials (e.g., rubber, linoleum) have natural antibacterial properties; others achieve 99.9% antibacterial rate via silver ion addition. With a surface friction coefficient ≥0.6, it effectively prevents slips in damp environments.

II. Main Disadvantages

1. Poor Heat Resistance & Susceptibility to Sharp Damage

· Heat Intolerance: PVC-based resilient flooring softens, deforms, or discolors when exposed to high temperatures (e.g., hot water bottles, cigarette butts, hot pots) for extended periods—avoid direct contact with high-temperature objects. Linoleum and cork have slightly better heat resistance but should also be kept away from open flames.

· Susceptible to Sharp Scratches: While wear-resistant, the surface is prone to permanent scratches from sharp objects (e.g., blades, metal furniture legs, pet claws). Low-density PVC is particularly vulnerable—use furniture foot pads and avoid dragging sharp items.

2. Quality Differentiation Due to Material Variances

· Eco-risk of Low-cost Products: Some low-end PVC resilient flooring may contain inferior plasticizers and stabilizers, leading to excessive VOC emissions that affect indoor air quality. Choose products with eco-certifications.

· Deformation of Natural Materials: Linoleum and cork are sensitive to humidity—shrinkage or bulging may occur in overly dry or humid environments. Maintain indoor humidity at 40%-60% and reserve expansion gaps during installation.

3. Installation & Post-use Limitations

· High Substrate Requirements: Flooring requires a flat, dry, crack-free substrate. Poor substrate quality causes bulging or curling. Some roll products need special adhesives for fixation, making later replacement cumbersome—adhesive quality may also impact eco-friendliness.

· Unsuitable for Outdoor Use: Most resilient flooring (especially PVC and linoleum) has poor UV resistance, fading and aging when exposed to sunlight for long periods. Only a few specialized rubber materials are suitable for semi-outdoor scenarios.

4. "Plastic-like" Texture

· Mid-to-low-end PVC resilient flooring, despite realistic appearances, has a distinct "plastic-like" touch compared to solid wood and natural stone. High-end linoleum and cork improve texture but come with higher prices, limiting widespread adoption.

Tip: Advantages and Disadvantages Depend on Scenarios

The pros and cons of resilient flooring are highly scenario-dependent. For residential and commercial spaces, its wear resistance, easy maintenance, water resistance, and safety cover core needs, while drawbacks like poor heat resistance can be avoided through usage habits (e.g., avoiding high temperatures, using protective pads). However, it may not be suitable for scenarios requiring natural textures, long-term outdoor use, or frequent high-temperature exposure. Overall, its "cost-effectiveness + practicality" makes it one of the fastest-growing flooring categories globally.

What Are the Installation Methods for Resilient Flooring?

Resilient flooring installation methods depend on material type (e.g., PVC, rubber, linoleum, cork), product form (rolls, click-lock tiles, sheets), and application scenario (residential, commercial). The core principles are: qualified substrate, suitable installation process, and guaranteed stability and eco-friendliness. Below are mainstream industry installation methods, including process details, application scenarios, and precautions—suitable for professional construction and home DIY.

I. Core Prerequisite: Pre-installation Substrate Preparation

Regardless of the method, substrate preparation directly determines installation quality and service life, requiring four key criteria: "flat, dry, clean, and stable":

1. Flatness: Use a 2-meter straightedge—height difference ≤3mm/2m; level with self-leveling cement if necessary.

2. Dryness: Concrete substrate moisture content ≤3% (for PVC/rubber) or ≤5% (for linoleum/cork) to avoid bulging from moisture.

3. Cleanliness: Remove dust, oil, and cracks from the substrate; fill cracks with repair agent.

4. Stability: Ensure no loose or hollow areas. For renovation of existing flooring, ensure stability—click-lock resilient flooring can be laid directly over old flooring without removal.

Additionally, resilient flooring should be acclimated to the environment 24-48 hours before installation to avoid deformation from temperature and humidity differences. Installation environment: temperature 18-26℃, humidity 40%-60%.

II. Four Mainstream Installation Methods: Process, Scenarios, and Advantages

1. Click-Lock Floating Installation

· Core Principle: No adhesive required. Tiles are joined via edge click-lock structures, with the entire flooring "floating" above the substrate (not fixed) and maintained as a whole by interlocking.

· Suitable Products: Click-lock LVT, WPC/SPC, click-lock cork flooring (sizes: 300×600mm, 600×1200mm).

· Construction Steps:

After leveling and cleaning the substrate, lay a moisture barrier (PE film or non-woven fabric, 2-3mm thick). Overlap seams by 5-10cm and fix with tape.

Start laying from the long side against the wall, with tile grooves facing the wall—reserve 8-10mm expansion gaps for thermal expansion.

Connect subsequent tiles via "tap-and-lock"—stagger horizontal seams by ≥30cm to avoid continuous seams affecting stability.

Install skirting boards to cover expansion gaps after completion.

· Advantages: Easy installation (DIY-friendly), short construction cycle, detachable and reusable, adhesive-free—suitable for residential spaces (living rooms, bedrooms, children’s rooms) and temporary spaces.

· Precautions: High substrate flatness required (height difference ≤2mm/2m) to avoid loose locks or floor noise; not suitable for long-term damp environments (e.g., unwaterproof bathrooms).

2. Full Spread Adhesive Installation

· Core Principle: Fully bond resilient flooring (rolls or sheets) to the substrate with specialized adhesive, enhancing adhesion and preventing displacement and bulging.

· Suitable Products: PVC rolls, rubber rolls/sheets, linoleum flooring, commercial LVT sheets (high-foot-traffic scenarios).

· Construction Steps:

After qualifying the substrate, snap lines to position the flooring for neat installation.

Apply specialized adhesive evenly to the substrate with a notched trowel (PVC adhesive for PVC, rubber adhesive for rubber, eco-friendly water-based adhesive for linoleum). Coverage ≥95% (100% for commercial scenarios).

After the adhesive "tacks off" (finger-touch dry, 15-30 minutes), lay the flooring slowly, press firmly, and roll to expel air—ensure no bubbles.

Weld seams of roll flooring with a welding gun (PVC welding rod for PVC rolls, rubber welding rod for rubber rolls)—weld width 3-5mm to enhance sealing.

Allow the adhesive to fully cure for 24-48 hours before cleaning and use.

· Advantages: Strong stability, anti-displacement, better sound insulation—suitable for commercial spaces (hospitals, schools, offices, malls), damp environments (bathrooms, kitchens), and high-foot-traffic areas.

· Precautions: Choose eco-friendly adhesive (e.g., FloorScore® certified) to avoid excessive VOCs; control adhesive thickness to prevent overflow and floor contamination; avoid stepping or placing heavy objects during curing.

3. Perimeter Bond Installation

· Core Principle: Apply adhesive only within 10-15cm of the tile edges for fixation, leaving the middle area adhesive-free to reserve expansion space—between floating and full adhesive installation.

· Suitable Products: PVC sheets, linoleum sheets (residential or low-foot-traffic commercial scenarios).

· Construction Steps:

Substrate preparation and line snapping same as full adhesive installation.

Apply adhesive only to tile edges and seams—no adhesive in the middle.

Lay the flooring, press the edges firmly, weigh down the edges to fix, and cure for 24 hours.

· Advantages: Balances stability and flexibility, higher installation efficiency than full adhesive—suitable for residential or small commercial spaces (e.g., small offices, shops) with flat substrates.

· Precautions: Not suitable for high-foot-traffic or heavy furniture areas to avoid edge curling; ensure tight seams to prevent dust and moisture infiltration.

4. Loose Lay Installation

· Core Principle: No adhesive or click-lock required. Flooring is fixed by its own weight and edge trim, laid directly on the substrate—easily detachable and replaceable.

· Suitable Products: Heavy-duty PVC rolls (thickness ≥3mm), commercial resilient sheets (high density, heavy weight).

· Construction Steps:

After qualifying the substrate, lay the flooring directly and align seams (no welding—just tight splicing).

Install edge trim (metal or PVC) around the room to fix the flooring edges and prevent displacement.

For large areas, use double-sided tape to assist in fixing seams and avoid curling.

· Advantages: Extremely easy installation/dismantling, eco-friendly (no adhesive), low maintenance cost—suitable for temporary spaces (e.g., exhibitions, rental offices), frequent flooring replacement scenarios, or renovation projects.

· Precautions: Only suitable for flat, dry, vibration-free substrates; avoid high-foot-traffic or heavy equipment areas to prevent displacement and wrinkling; ensure firm installation of edge trim to avoid edge curling.

III. Key Installation Precautions

1. Expansion Gap Reservation: All resilient flooring installations require 8-15mm expansion gaps (along walls, columns, thresholds)—≥15mm for large areas—to avoid bulging and deformation from temperature changes.

2. Adhesive Selection: Use specialized adhesive matching the flooring material (e.g., PVC adhesive for PVC, rubber adhesive for rubber) to avoid detachment due to incompatibility. Prioritize water-based eco-friendly adhesive to reduce formaldehyde and VOC emissions.

3. Seam Handling: Weld seams of roll flooring (mandatory for commercial scenarios); splice sheet seams tightly to avoid water and dust infiltration. Ensure full interlocking of click-lock tiles to prevent later noise.

4. Post-installation Maintenance: Avoid stepping or placing heavy objects within 24-48 hours to ensure adhesive curing. Prevent sharp scratches and direct high-temperature contact during daily use to extend service life.

Tip:

Resilient flooring installation methods are selected based on "material characteristics + application scenarios": click-lock floating installation for residential spaces (convenient and eco-friendly), full adhesive installation for high-foot-traffic commercial scenarios (stable and durable), and loose lay installation for temporary spaces (flexible and detachable). Regardless of the method, substrate preparation and expansion gap reservation are critical to installation quality and service life. For large-scale commercial projects, professional construction teams are recommended; home DIY is feasible for small-scale installation (e.g., bedrooms, studies) with click-lock resilient flooring—strictly follow substrate preparation requirements.

Major Global Flooring Manufacturers

Based on global market structure, segment advantages, and authoritative industry rankings, international resilient flooring manufacturers are classified by mainstream materials (PVC, rubber, linoleum, cork) and segment leadership—covering century-old brands and innovative enterprises:

I. Core PVC-based Resilient Flooring Manufacturers (90% Global Market Share, Dominating Mainstream Segments)

PVC is the core material for resilient flooring, including LVT, multi-layer rolls, homogeneous rolls, and VCT. The following manufacturers lead in technology, output, and brand influence:

1. Mannington (USA)

o Founded: 1915

o Core Advantages: Global leader in LVT; strengthened high-end LVT market position via acquisition of Amtico (UK). Rich product colors, mature click-lock technology, adapting to commercial (office, retail) and residential scenarios. Also supplies PVC rolls and rubber flooring.

o Market Position: Representative high-end LVT brand, top market share in the US and Europe—renowned for design innovation and durability.

2. Mohawk Industries (USA)

Founded: 1825

Core Advantages: One of the world’s largest flooring enterprises, global leader in PVC multi-layer rolls. Expanded global production capacity via acquisition of IVC Group (Belgium). Full product range includes LVT, VCT, and multi-layer rolls—balancing cost-effectiveness and scale.

Market Position: Covers commercial and residential markets, distribution network in over 100 countries—sales champion in North America’s resilient flooring market.

3. Tarkett (France)

Founded: 1886

Core Advantages: Full-range resilient flooring giant, dominant in homogeneous rolls (healthcare, nursing home scenarios) with global-leading output and product diversity. Also 布局 LVT, VCT, rubber flooring, and linoleum—expanded industrial chain via acquisitions (e.g., Johnsonite, Fieldturf).

Market Position: Core supplier for commercial scenarios (healthcare, education, transportation) with comprehensive eco-certifications (Cradle to Cradle, LEED). Top market share in homogeneous rolls for China’s healthcare sector.

4. Armstrong (USA)

Founded: 1860

Core Advantages: Century-old flooring brand, former global sales champion in VCT. Product range includes PVC rolls, sheets, and rubber flooring. Entered China in 1985 with a factory in Suzhou—early layout in the Asia-Pacific market, mature floor-wall integrated solutions.

Market Position: Leading mid-range commercial and residential brand with high cost-effectiveness—suitable for high-foot-traffic scenarios like schools and offices.

5. Gerflor (France)

Founded: 1937

o Core Advantages: Global leader in PVC sports flooring; Taraflex series is the official flooring for international events (basketball, volleyball). Also supplies medical PVC rolls and slip-resistant flooring with excellent antibacterial properties and durability—sales network in over 50 countries.

Market Position: Expert in high-end commercial (sports, healthcare) scenarios—combining eco-friendliness and functionality, a core brand in Europe’s resilient flooring market.

Gerflor: https://www.gerflor.com/

PVC sports flooring: https://www.domotexasiachinafloor.com/Product-Categories/

6. Polyflor (UK)

Founded: 1915; Click to view Polyflor (https://www.polyflor.com)

Core Advantages: Famous for high-slip-resistant PVC flooring—adapting to healthcare, catering, and transportation scenarios. Launched the first PVC flooring in 1948 with profound technical accumulation, strong customization capabilities for colors and sizes. Also supplies rubber flooring and sports flooring.

Market Position: Segment champion in commercial slip-resistant flooring—high recognition in Europe and Asia-Pacific’s healthcare sector.

II. Core Rubber-based Resilient Flooring Manufacturers (Leaders in High-end Commercial Scenarios)

Rubber flooring, with super wear resistance, impact resistance, and easy disinfection, targets high-end scenarios like airports, hospitals, and sports venues. International top brands are concentrated in Europe and the US:

1. Nora Systems (Germany)

Founded: 1949 Click to view Nora Systems: https://www.interface.com/US/en-US.html

Core Advantages: Global leader in rubber flooring, offering over 200 colors and patterns—combining functionality and design. Annual turnover exceeding €152 million, top market share in Europe and the US. Entered China in 1997, completing landmark projects like Beijing Daxing International Airport and Shanghai Ruijin Hospital.

Market Position: Benchmark for high-end rubber flooring—suitable for airports, luxury stores, and high-end hospitals.

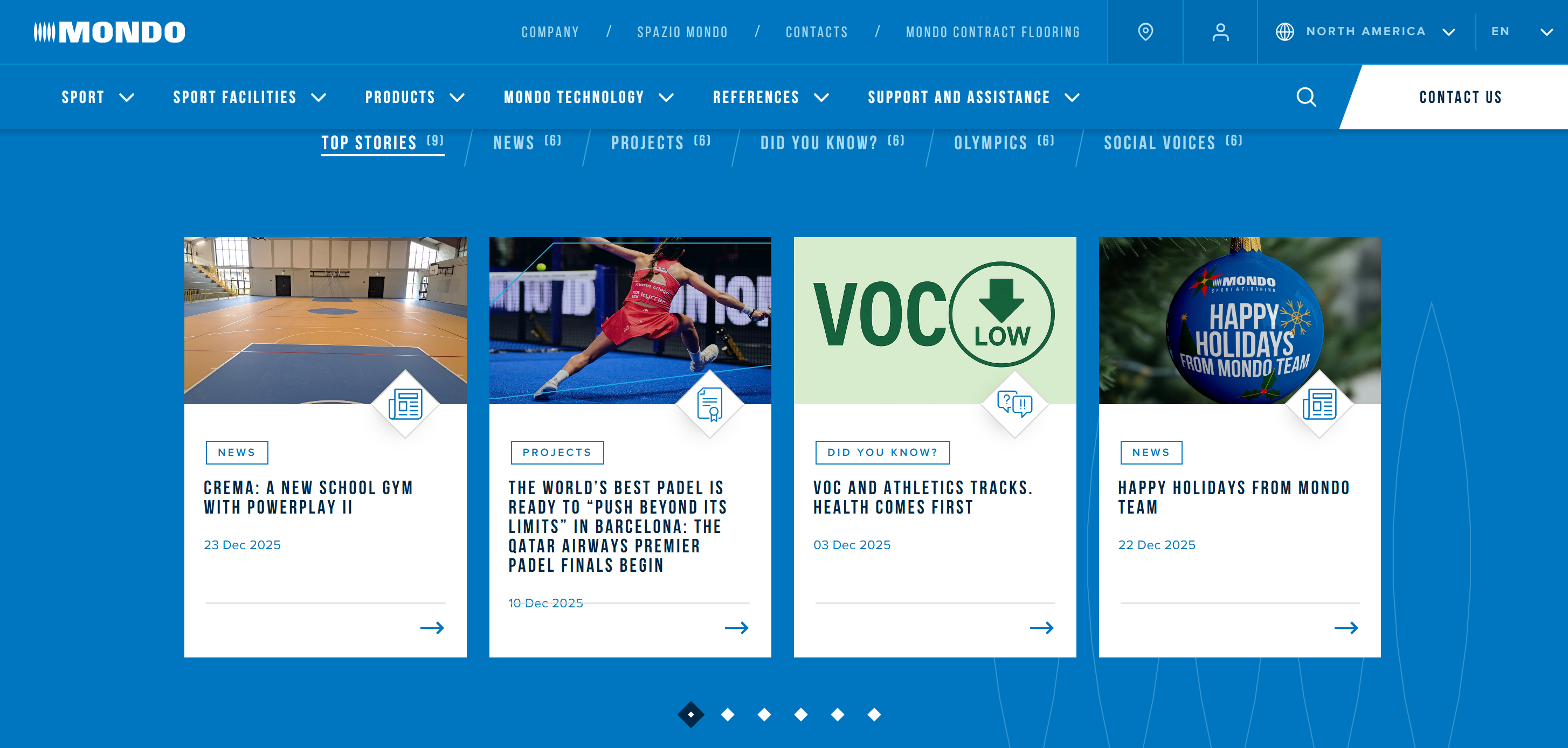

2. Mondo (Italy)

Founded: 1948

Core Advantages: Global leader in sports rubber flooring, long-term supplier for international events like the Olympic Games and F1 tracks. Also supplies commercial flooring, business in over 190 countries. Established a factory in China in 2005 with strong production capacity and localized service.

Market Position: Dual development in sports scenarios and high-end commercial—high technical barriers (e.g., self-healing rubber technology).

https://www.mondoworldwide.com/na/en/

3. Johnsonite (USA, now part of Tarkett Group)

Core Advantages: Expert in rubber flooring and wall base systems. Integrated global resources after acquisition by Tarkett—products feature antibacterial and sound insulation properties, adapting to hospitals and offices. Top market share in North America.

III. Core Linoleum-based Resilient Flooring Manufacturers (Eco-friendly Niche Segment)

Linoleum flooring, with 100% natural materials and biodegradability, has a small market share (less than 5%) due to high costs. International brands are concentrated in Europe:

1. Forbo (Switzerland)

Founded: 1928

Core Advantages: Absolute global leader in linoleum flooring—certified by LEED Platinum and Cradle to Cradle. Rich colors (mature digital printing technology), adapting to kindergartens, nursing homes, and green building projects. Also supplies PVC flooring and carpets—comprehensive commercial scenario solutions.

Market Position: Benchmark for eco-friendly flooring—preferred brand for green building projects in Europe and North America.

https://www.forbo.com/flooring/en-us/

2. Tarkett (France)

Supplementary Advantages: Secondary player in linoleum flooring. Leverages full-range layout to provide "PVC + linoleum" combined solutions—suitable for commercial scenarios with basic eco-requirements and limited budgets.

IV. Core Cork-based Resilient Flooring Manufacturers (Niche High-end Segment)

Cork flooring, known for comfortable foot feel and sound insulation, relies on Mediterranean cork oak for raw materials. International brands are concentrated in Portugal (global cork hub):

1. Amorim (Portugal)

Founded: 1872

Core Advantages: Global cork industry giant, holding over 60% of the global cork flooring market share. Wicanders series features personalized customization (e.g., wood grain, abstract patterns), adapting to high-end residences and sound studios—outstanding eco-friendliness (recyclable raw materials).

Market Position: The only global first-tier cork flooring brand—strong technical and raw material monopoly.

https://www.amorimcorkflooring.com/

2. Jelinek Cork Group (Canada)

Core Advantages: Leading North American cork flooring brand. Relies on Amorim’s raw material supply to offer cost-effective cork products—adapting to mid-to-high-end residential and small commercial scenarios with a sound North American distribution network.

https://jelinek.com/jelinek-cork-flooring

V. Global Comprehensive Flooring Groups (Cross-material Layout, Resilient Flooring as Core Business)

Some international giants have become key players in the resilient flooring market through multi-category layout and acquisitions, covering hardwood, carpets, and other flooring materials:

1. Shaw Industries (USA, owned by Berkshire Hathaway)

Core Advantages: Second-largest flooring seller in North America. Resilient flooring business focuses on LVT and PVC rolls—prioritizing eco-friendliness (low-VOC adhesive, recycled raw materials) and digital design (3D wood grain printing). Stable cooperation with commercial clients (e.g., Marriott Hotel Group).

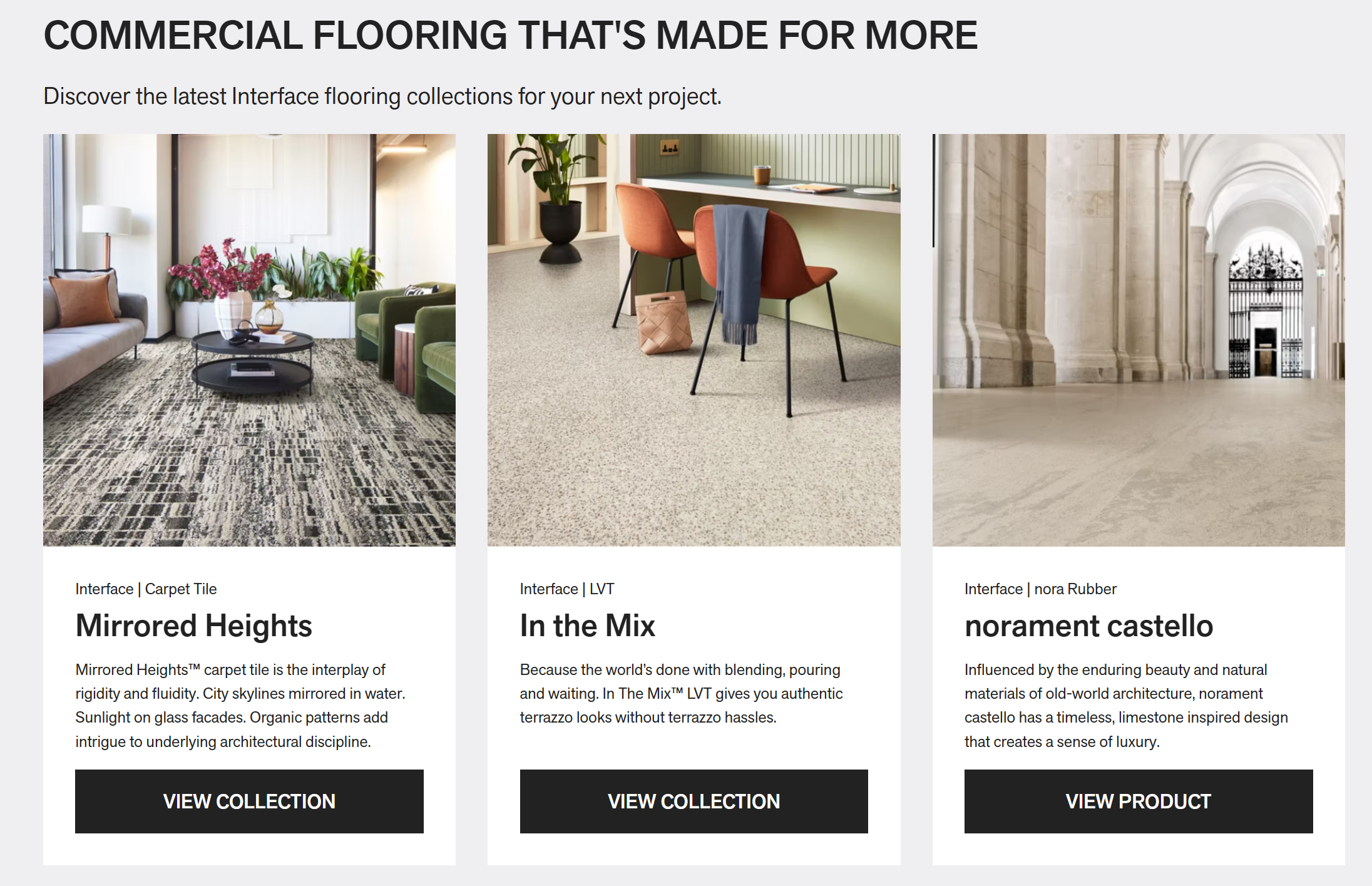

2. Interface (USA)

Core Advantages: Famous for carpet tiles, with rapidly growing resilient flooring business (PVC, rubber). Focuses on carbon-neutral products (full-life-cycle carbon neutrality), adapting to green offices and science parks—leading the industry in sustainable development concepts.

https://www.interface.com/US/en-US.html

Tip: Core Characteristics and Selection Recommendations for International Manufacturers

1. Segment-focused Brands: e.g., Nora (rubber), Amorim (cork), Forbo (linoleum)—suitable for high-end scenario-specific material needs (e.g., Nora for high-end hospitals, Forbo for green buildings).

2. Full-range Giants: e.g., Tarkett, Mohawk, Armstrong—suitable for commercial projects requiring "one-stop flooring solutions" (e.g., complexes, industrial parks).

3. Regional Advantage Brands: e.g., Mannington (North American LVT), Mondo (European sports flooring)—consider localized service capabilities for target markets.

These manufacturers form the global competitive landscape of resilient flooring. Their technological innovations (e.g., click-lock, carbon-negative processes) and eco-friendly practices (recycled raw materials, carbon neutrality) also lead the industry’s future direction.

Global Building Materials Retailers and Wholesalers of Resilient Flooring

Resilient flooring, encompassing PVC, LVT, linoleum, rubber, and SPC variants, has become a cornerstone in residential, commercial, and industrial construction worldwide. The global distribution network of these flooring solutions relies on three core player types: international integrated building materials retailers, specialized flooring wholesalers, and regional niche distributors. These entities bridge manufacturers—such as Shaw Industries, Tarkett, and Gerflor—and end-users, delivering tailored products, technical support, and efficient logistics across diverse markets.

These retailers excel in one-stop home improvement solutions, boasting extensive store networks and dual retail-wholesale capabilities. They cater to homeowners, small contractors, and boutique commercial projects, combining product accessibility with user-friendly services.

1. The Home Depot (USA)As the world’s largest home improvement retailer, it operates over 2,300 stores across North America, Canada, and Mexico. Resilient flooring accounts for 35% of its flooring category revenue, featuring partnerships with top brands like Mohawk, Armstrong, and Mannington. Its product range spans LVT planks, VCT tiles, commercial PVC rolls, and eco-friendly options like Forbo linoleum and Amorim cork flooring. It offers online selection, in-store sample displays, DIY installation guides, and bulk purchase discounts (15% off orders over $5,000), dominating 40% of the North American residential resilient flooring market with 2023 wholesale revenue exceeding $1.2 billion.

The Home Depot: https://www.homedepot.com/

2. Lowe’s (USA)North America’s second-largest home improvement retailer runs 1,700+ stores, focusing on cost-effective and scenario-specific resilient flooring solutions. It exclusively distributes Coretec (Shaw’s premium LVT line) and Gerflor’s healthcare-grade anti-slip flooring, catering to small hospitals and kindergartens. Services include BOPIS (Buy Online, Pick Up In-Store), free on-site measurement for commercial clients, and a 2024-launched resilient flooring recycling program. With a 28% North American market share, its Canadian and Australian stores feature dedicated Asian import sections, offering high-value products from LG Hausys and Power Dekor.

https://www.lowes.com/

3. B&Q (UK)A leading European home improvement retailer with a strong presence in Asia, it operates over 50 stores in China plus locations across Southeast Asia. In Europe, it prioritizes eco-certified resilient flooring, such as Forbo linoleum (Cradle to Cradle Silver Certified) and Polyflor anti-slip PVC. In China, it balances international brands (Tarkett PVC rolls, Armstrong rubber flooring) with domestic leaders like Tarzen SPC flooring, offering "floor-wall integration" packages. Adapted to regional needs, its Southeast Asian stores provide moisture-resistant solutions with in-store humidity testing, while UK locations offer up to 15% trade-in discounts for old flooring.

B&Q: https://www.diy.com/

II. Specialized Flooring Wholesalers (B2B-Focused, Commercial & Industrial Expertise)

These B2B-focused entities specialize in bulk distribution, custom solutions, and technical compliance for large-scale projects. They serve property developers, construction firms, and corporate clients, excelling in high-performance and industry-specific resilient flooring.

1. Floor & Decor (USA)North America’s top specialized flooring wholesaler derives 62% of its 2023 revenue from resilient flooring, focusing on commercial and industrial clients. Its portfolio includes Shaw’s high-wear PVC rolls for malls, Gerflor’s FIBA-certified Taraflex sports flooring, and Nora’s ICU-specific rubber flooring. It supports custom color and thickness options with a 1,000㎡ minimum order, complemented by 12 regional warehouses enabling 48-hour domestic delivery. For large projects like airport terminals, it offers phased supply and LEED/WELL certification support teams.

https://www.flooranddecor.com/

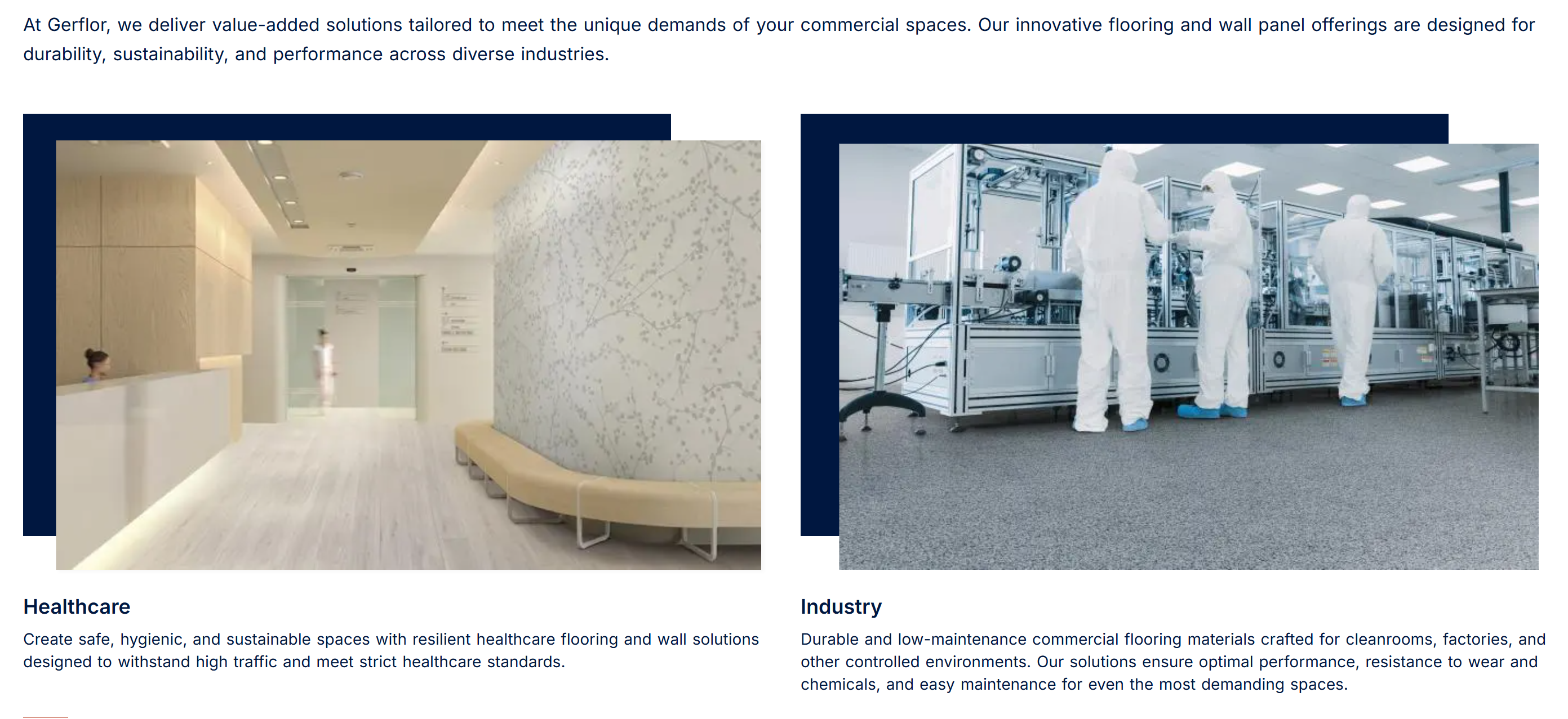

2. Gerflor Global Distribution Network (France)A dedicated distribution system for Gerflor—one of the world’s top 3 resilient flooring brands—covering 100+ countries via 30 subsidiaries and 200+ authorized wholesalers. It exclusively supplies Gerflor’s premium lines: Taraflex sports flooring (Olympic-approved), Mipolam BioControl conductive flooring (meets IEC61350-5-1/ANSI ESD S20.20 standards for electronics factories), and DLW linoleum. Services include technical training, installation guidance, lifetime warranties for ESD flooring, and 2024-launched carbon footprint tracking for each batch.

https://www.gerflor.com/

3. Shaw Contract (USA, Shaw Industries Subsidiary)Founded in 1946, this commercial-focused wholesaler generated over $800 million in 2023 revenue, serving Marriott, Hilton, Amazon, and Microsoft. Its sustainable resilient flooring lineup includes EcoWorx (LVT with 40% recycled PVC), LokDots glue-free lockable rolls (50% faster installation), and Coretec Gao (IPX7 waterproof SPC flooring). It offers an online Design Studio for custom patterns and global uniform supply standards for multinational chains, plus old flooring recycling programs to support carbon neutrality goals.

4. Fastenal (Global Industrial Wholesaler)With 3,200 stores worldwide, it specializes in industrial-grade resilient flooring for electronics factories, data centers, and warehouses. Its core products include Gerflor GTI ESD tiles (10^6-10^9Ω surface resistance, glue-free) and Shaw’s conductive rubber flooring, plus heavy-duty rubber flooring resistant to forklift traffic (15+ year lifespan). It provides JIT (Just-In-Time) delivery with minimum orders as low as 100㎡ and regular ESD compliance testing for industrial clients, achieving $580 million in 2023 industrial resilient flooring revenue.

III. Regional Niche Distributors (Localized Coverage, Market-Adapted Solutions)

These distributors deepen regional penetration by aligning with local building codes, climate conditions, and consumer preferences, blending international product access with on-the-ground support.

1. Oriental Yuhong Building Materials Distribution (China)China’s leading building materials distributor generated $120 million in 2023 resilient flooring revenue, covering 30 domestic provinces and exporting to Southeast Asia/Middle East. It represents international brands (Tarkett PVC rolls, Armstrong rubber flooring) and domestic leaders (Kentier LVT, Senking cork flooring). For China’s humid south, it offers moisture-proof PVC rolls (≤2% moisture content) for basements and bathrooms, with regional warehouses enabling next-day delivery and support for GB/T 4085-2015 compliance testing.

https://www.oyhglobal.com/

2. Torlys Distribution Partners (North America & Europe)A premium-focused regional wholesaler with 6 warehouses in Canada, Germany, and the UK, serving luxury retail stores, high-end hotels, and villas. It specializes in Amorim cork flooring (Portuguese-imported custom wood grains), Forbo LEED Platinum-certified linoleum, and exclusive Torlys Luxury LVT (3D digital-printed stone textures). Services include free 10×10cm sample testing (with wear/slip reports) and one-on-one designer consultations for projects like Michelin restaurants, adding carbon-neutral supply options in 2024.

Core Value of Retailers & Wholesalers

These global players bridge the gap between manufacturers and end users by: 1) Offering diverse product portfolios to meet different budget and functional needs; 2) Providing localized logistics and inventory management to ensure fast delivery; 3) Delivering professional services (installation consulting, technical training, after-sales support); 4) Adapting to regional market regulations and consumer preferences (e.g., eco-certifications in Europe, anti-slip standards in Asia). For industry participants, partnering with reputable retailers/wholesalers is key to expanding market reach and enhancing customer accessibility—especially as resilient flooring demand grows in residential and commercial sectors worldwide.

Resilient Flooring Outlook

Resilient flooring has emerged as the fastest-growing flooring category globally, thanks to its diverse materials, balanced performance, and wide adaptability. From residential spaces to professional venues, and from production to retail, a well-established global supply chain ensures its efficient circulation. As a core business platform in the Asia-Pacific region, DOMOTEX asia continuously drives technological innovation and market expansion of resilient flooring, providing industry participants with trend insights and business matching channels to help them accurately seize market opportunities.